RailPro®

| Company | Loram UK Ltd |

|---|

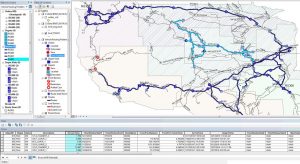

Images

Comprehensive Rail Grinding Management

Loram’s proprietary RailPro® system is an integrated suite of cutting-edge software tools designed specifically for comprehensive rail grinding management. The system relies upon Loram’s extensive intelligence base of specialized rail grinding knowledge, accumulated through decades of experience in the area of rail grinding and track maintenance. By combining this knowledge and experience with accurate rail condition and asset data, invaluable insights and information is produced that supports optimized, micro- and macro-level rail grinding program planning.

RailPro offers a completely integrated rail grinding management solution, including modules for data collection, rail inspection, grind performance monitoring, data management, analysis, and reporting, making the cyclical processes of a grind program more manageable. The system has been designed with both large and small railroads in mind, and can be customized and packaged in different configurations to meet specific needs.

A key component of the RailPro suite is the Inspection module. This software uses knowledge-based, predictive algorithms to analyze the rail condition and determine the grind passes, patterns, and speeds that will remove the optimal amount of metal while delivering precise rail profile control.

The rail profile and rail surface condition information required by the grind planning algorithms is typically acquired by a Rail Inspection Vehicle (RIV). Loram’s RIV is equipped with state-of-the-art hardware and software including optical Rail Profile Measurement System (RPMS), Rail Surface Monitoring Systems (RSMS), and RailPro Inspection software that enable the railroad to effectively perform timely, automatic pre-grind rail inspections. This automated inspection allows for more accuracy, consistency, and repeatability, which ultimately leads to cost savings through extending the life of your rail.