Rail Grinding

| Company | Loram UK Ltd |

|---|

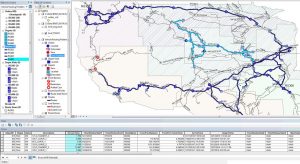

Images

Extend the Life of Your Rail

Rail grinding is the cornerstone of virtually every railroad maintenance program. To maximize the life and value of rail assets, precision removal of fatigued metal, restoration of the rail head profile and removal of rail defects are the optimization goals of an effective rail grinding program.

Loram’s comprehensive rail grinding services and equipment portfolio consists of:

- Production Rail Grinding

- Specialty Rail Grinding

- Transit Rail Grinding

Loram’s rail grinding solutions deliver substantial return on investment including:

- Extended rail life and track component life

- Improved wheel and rail interaction

- Prevention of premature rail failures and replacement

- Fuel savings

- Reduced wear on rolling stock

- Improved ride quality and passenger comfort

Superior technology and experience. The Loram difference.

Loram’s rail grinders incorporate high power, flexible grinding modules and patented control systems to deliver industry-leading speed and proven productivity. Loram’s rail grinding product portfolio offers machine configurations from 4 to 120 stones, providing the ideal rail grinding solution to any customer request. To ensure maximum ROI, Loram’s pre-grind inspection services help railroads plan, budget and optimize their programs.

As a global leader in rail grinding for over 50 years, Loram’s expansive rail grinding portfolio and highly-trained crews deliver best-in-class services and equipment with unmatched performance and safety standards.