Baseplated Crossing System

| Company | Rosehill Rail |

|---|

Images

Description

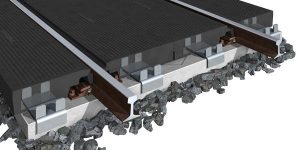

The Rosehill Baseplated crossing system has unique advantages over other more rigid systems which cannot adapt to bespoke site specific requirements. The solid rubber panels can be cut to fit around fishplates, check rails (single and double) turnouts and in rail sheds and depots. Panels can also be manufactured to fit around tight curves which is especially useful for tramway applications.

The system allows for very fast installation, is ideal for average sized crossings and is available in various grades to accommodate track access, depots, agricultural and pedestrian applications.

Our rubber road panels are manufactured from our highest grade formula and engineered for maximum wear resistance.

Features

- Panel dimensions are 1.8 metres long and half the gauge width. The cess panels are 1.8 metres long and can be manufactured to fit concrete or plastic edge beams.

- The panels are connected by baseplates and can be made to suit narrow, standard or wide gauge and any rail and sleeper.

- Complies with UK anti-skid requirements.

- Conforms to many international rail specifications.

Advantages

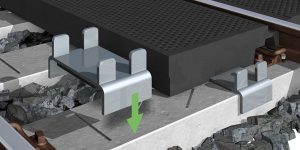

- As with all Rosehill designed panels, the Baseplated Crossing System is easy to install, just a simple baseplate which pulls the panels together.

- Site installation is fast and simple with no specialised tools required.

- Single panels can be removed and replaced from anywhere within the crossing area.

- The system can be manufactured to suit any gauge or rail type.

- Baseplates are not fixed to sleepers.

- Panels can also be installed in concrete Bomac type edge beams