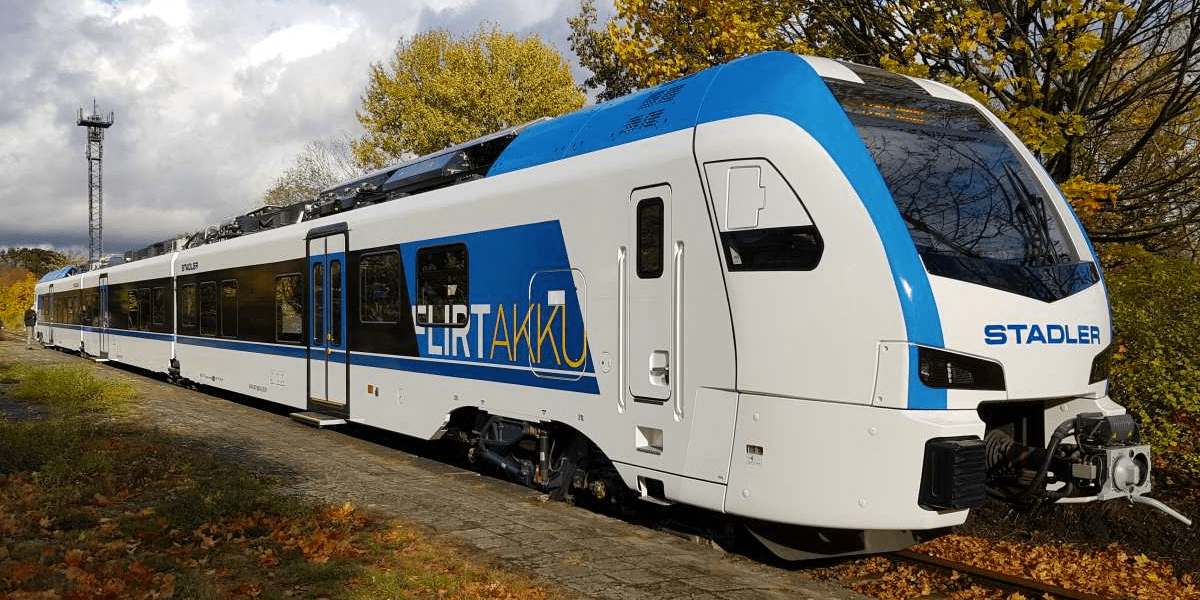

Battery trials on a Stadler train for Arriva Netherlands prove that they can run emission-free on non-electrified lines

Tests completed on a modified Stadler-built diesel-electric multiple unit demonstrate that trains are able to operate solely with batteries, on lines that are not electrified. This success underscores Stadler’s sustainability credentials and represents huge benefits for clients and society overall.

he successful completion of battery trials undertaken on a modified diesel-electric multiple unit built for Arriva Netherlands shows that these trains can run emission-free, without the use of a diesel generator, supporting the client’s carbon emission targets and enabling it to avoid costly infrastructure changes.

Tests were completed over the last few days on the non-electrified lines from Almelo to Hardenberg and Arnhem to Doetinchem, in the east of the Netherlands. This particular train runs with electric energy 1.5kV DC from the overhead line and uses the battery to bridge non-electrified sections.

The use of battery power enables trains to run independently on non-electrified lines and provides a more sustainable alternative to diesel. Batteries are used to power a train and can capture energy while it is braking. They can be charged from electrified lines or at designated charging-points on a network.

Battery trains produce fewer carbon emissions than diesel vehicles and are a very attractive alternative to them. They offer a fantastic solution for non-electrified lines, eliminating the need for costly infrastructure upgrades for transport organisations and governments.

Stadler has sold around 300 trains and locomotives with traction batteries in ten countries, including more than 110 FLIRT Akku for operation in three regions in Germany. In tests conducted last year, the battery-powered FLIRT Akku travelled more than 220km in battery-only mode, the longest distance on record and documented in the book of Guinness World Records. Stadler is currently building the first hydrogen-powered train ever to run in the US, ordered by the San Bernardino County Transportation Authority.

Dr Ansgar Brockmeyer, Executive Vice President Marketing & Sales and Deputy CEO of Stadler, commented: “These trials highlight the role that green technology can play in de-carbonising our world and bring us one step further to creating a truly green railway. Working closely with our clients, Stadler is committed to developing innovative ways of making the industry more sustainable, providing attractive and efficient rolling stock, to encourage modal shift for both passengers and freight.”

About Stadler

Stadler has been building trains for 80 years. The provider of mobility solutions in rail vehicle construction, service and signalling technology has its headquarters in Bussnang, eastern Switzerland. It has a workforce of around 13,000 based in various production and engineering locations as well as more than 60 service locations. The company is conscious of its social responsibility for sustainable mobility and therefore stands for innovative, sustainable and durable quality products. The product range in the field of mainline railways and city transport includes high–speed trains, intercity trains, regional and suburban trains, metros, tramways and trams. Stadler also manufactures main–line locomotives, shunting locomotives and passenger carriages.

It is the world’s leading manufacturer in the rack–and–pinion rail vehicle industry.