Battery trials in the Netherlands demonstrate Stadler’s commitment to green technology and producing sustainable trains

Tests to find out whether Arriva Netherlands’ trains can travel in battery mode are about to start in the Netherlands, in the wake of several recent successes for Stadler in the area of green technology, positioning it as a pioneer in this field. Achievements secured to date illustrate the significant role that alternative traction can play in de–carbonising rail travel and highlight how it can help companies and governments meet emission targets.

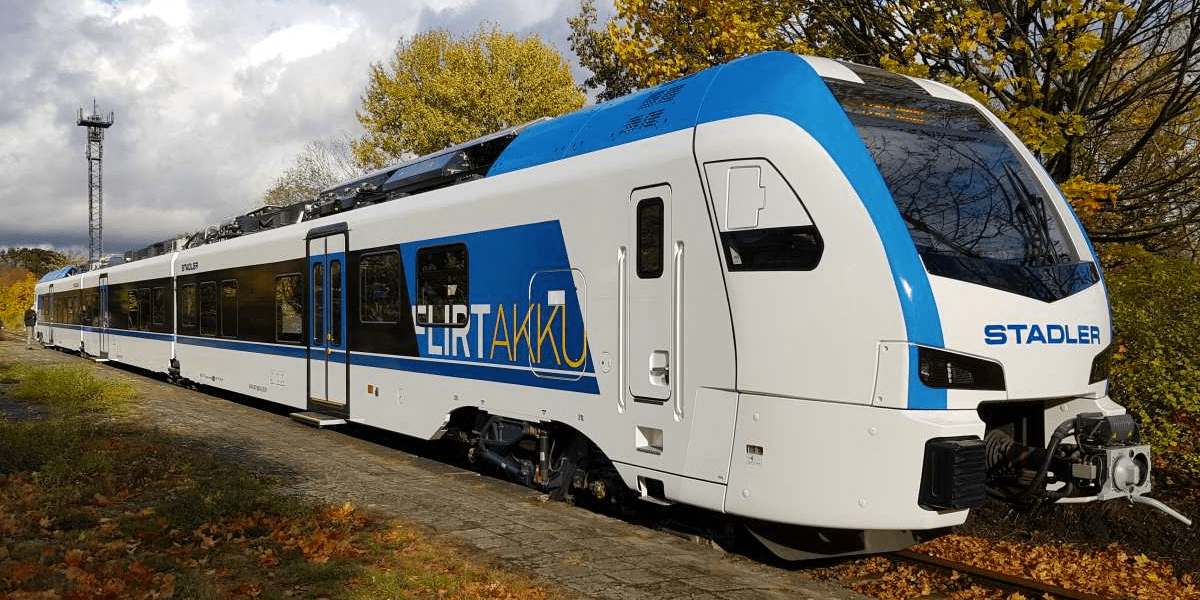

- Stadler has sold around 300 trains and locomotives with traction batteries in ten countries, including more than 110 FLIRT Akku trains for three regions in Germany.

- In tests last year, the FLIRT Akku travelled more than 220km in battery–only mode, the longest distance on record and documented in the Guinness World Records book.

- Stadler is currently building the first hydrogen–powered train ever to run in the US, ordered by the San Bernardino County Transportation Authority.

The latest tests about to start on battery trains for Arriva Netherlands illustrate Stadler’s commitment to the environment, its mission to help de-carbonise the railway and the important contribution it can make in enabling clients, transport authorities and national governments around the world to cut carbon emissions.

The trials will show the effectiveness of battery-powered trains for use on non-electrified lines and will be conducted on a modified WINK train, using recuperated braking energy to power the train. They will take place overnight this week in the east of the Netherlands.

Stadler has sold approximately 300 trains and locomotives with traction batteries in ten countries, including the Netherlands, the UK, the US, Germany, Italy, Austria, Norway, Spain, Poland and Switzerland. It has a proven track record in the area, deploying battery technology in trains, trams, tram-trains, metros and locomotives.

For diesel multiple units, the battery technology that Stadler deploys involves capturing energy while a train is braking in order to cut carbon emissions. For locomotives, batteries are used to enable them to travel emission-free for the last mile of their journey and while they are being shunted. On trams, tram-trains and metro trains, the use of batteries means that they can travel short distances on non-electrified lines. Batteries allow electric multiple units to cover long distances on non-electrified lines.

Last year, tests were undertaken in Germany on a prototype of a FLIRT Akku, the battery electric multiple unit made by Stadler. Carried out in very wintry conditions, the trials saw the train cover 224km in battery-only mode, the longest distance a battery train is known ever to have travelled, and securing Stadler a mention in the prestigious book of Guinness World Records.

These tests were the culmination of a three-year research project into developing and testing battery technologies for rolling stock. The project provided Stadler with valuable insights and helped further its long-term aspiration to develop carbon emission-free rolling stock around the world. In July 2019, it signed a contract with Schleswig-Holstein for 55 battery-powered FLIRT Akku multiple-units. Last year, it won an order for 44 FLIRT two-car units for Pfalznetz, a rail network in south west Germany. DB Regio ordered 14 additional FLIRT Akku, replacing the old diesel-powered trains in northern Germany, just this month.

Two years ago, Stadler won its first ever bid for a hydrogen-powered train, the first of its type ever to be ordered in the US. Supporting the country’s aspiration to introduce zero-emission passenger rail technology, the contract was with the San Bernardino County Transportation Authority, and includes the option for four more to be supplied in future.

Stadler aims to make the railways more sustainable, by providing attractive and efficient rolling stock, to encourage modal shift for both passengers and freight. Its products consume the least amount of energy possible, relying on light, recyclable material to minimise environmental impact and increase energy efficiency.

Lightweight aluminium is used for carbodies, and traction equipment is controlled by state-of-the-art software. A keen emphasis is put on design, with much of its rolling stock featuring maximum efficiency drive technology, and bi-mode traction drives. Sub-systems and components rely on up-to-date innovative technologies and procedures. Stadler selects suppliers based on their proximity to its production sites, as well as the means of

the transport and packaging that they use.

All of these polices are underpinned by modern signalling systems, which can be installed in the train. One of these is ATO (Automatic Train Operation). ATO involves a computer to determine the speed at which trains travel, in order to maximise operational and energy efficiency. Stadler Signalling, in co-operation with ProRail and Arriva in the Netherlands, recently worked on an ATO pilot-scheme, which has proved successful.

Dr. Ansgar Brockmeyer, Executive Vice President Marketing & Sales and Deputy CEO of Stadler, said: “We firmly believe that Stadler can play a critical role in making travel more sustainable and helping societies all over the world cut carbon emissions. Our two-pronged approach is to make electric trains more efficient and to develop effective solutions for networks that are not yet electrified. By heightening efficiency on the railway

and making rail more attractive and more competitive, we can promote modal shift, for both passengers and freight. With more than 100 FLIRT Akku sold, we have manifested our market leadership in the field of alternative drives.”

Stadler in the Netherlands

280 trains have been delivered to clients in the Netherlands, including Arriva Netherlands, QBuzz, Keolis, NS

and Connexxion. Stadler services trains in Leeuwarden, Venlo, Hengelo and has a re-fit location in Blerick. In total, Stadler Service Netherland is responsible for servicing 165 trains, employs 160 people and is headquartered in Apeldoorn.